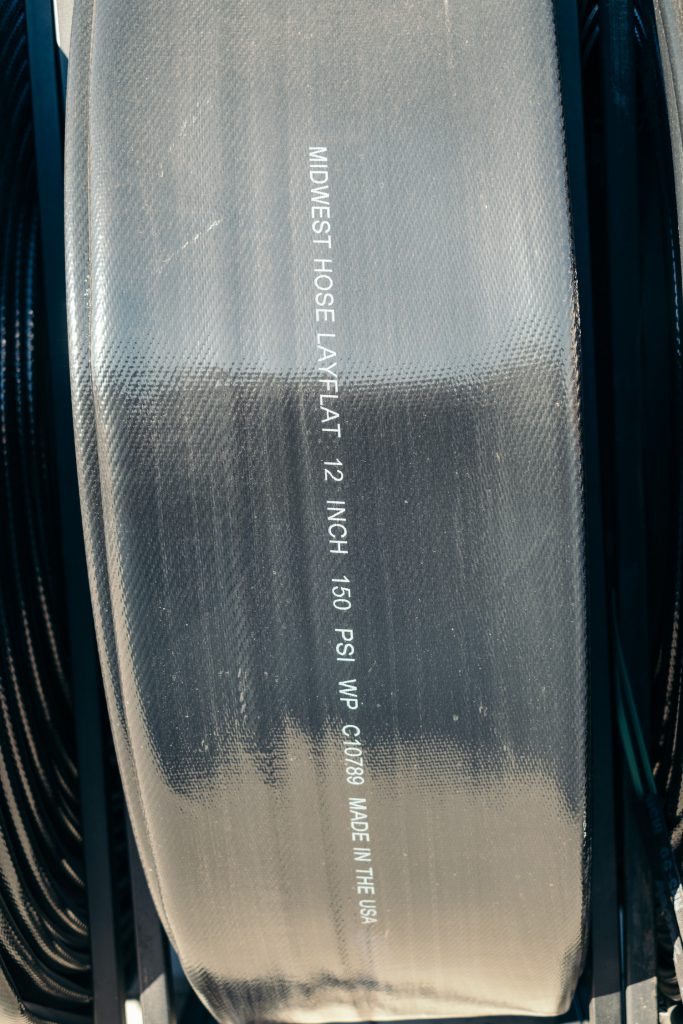

TPU Layflat

Designed for produced water/fresh water transfer. Typically used for hydraulic fracture water transfer, to replace damaged hydrant lines, or to replace a broken water main. Manufactured with NSF standard 61 approved materials for use with potable water.

Construction Polyurethane Extruded Through the Weave and a Circular Polyester Woven Reinforcement. No use of glues or adhesives.

Safety Factor Minimum 2.5 to 1

Lining Properties

Ultimate Tensile Strength no less than 1200 psi

Ultimate Elongation when tested to UL-19 guidelines a small dumbbell sample of lining elongates a minimum of 400%

Resistance

Abrasion 25mm on DIN 53516/ISO4649 testing, up to 5 times more resistant and 50% more puncture resistant than Nitrile/PVC

Cold Remains flexible in as low as -40°F conditions

Ozone No cracking in lining or cover when tested to ASTM D518 Procedure B (100 pphm/118°F/70 hours)

Chemical Resistant to most chemicals and petroleum products

Temperature -40°F to 180°F

Custom hose color and branding available on big volume orders.

All assemblies are proof tested at working pressure in the USA. We take a great deal of pride in promising that only the highest quality product leaves through our doors.

| ID | Wall Thickness | Max W.P. | Elongation | Weight | Weight per Reel Length | Reel Length | Empty Reel Weight |

|---|---|---|---|---|---|---|---|

| inch | inch | psi | at W.P. | lbs./ft. | lbs | feet | lbs |

| 4 | 0.157 | 250 | 1.0% | 1.01 | 666 | 660 | |

| 6 | 0.161 | 250 | 1.0% | 1.61 | 1,062 | 660 | |

| 8 | 0.165 | 200 | 0.7% | 2.15 | 1,419 | 660 | |

| 10 | 0.165 | 200 | 0.5% | 2.87 | 1,894 | 660 | 221 |

| 12 | 0.196 | 200 | 0.5% | 3.73 | 2,462 | 660 | 243 |

| 14 | 0.215 | 150 | 1.0% | 4.20 | 2,500 | 528 | 285 |

| 16 | 0.215 | 125 | 1.0% | 5.00 | 2,850 | 528 | 285 |